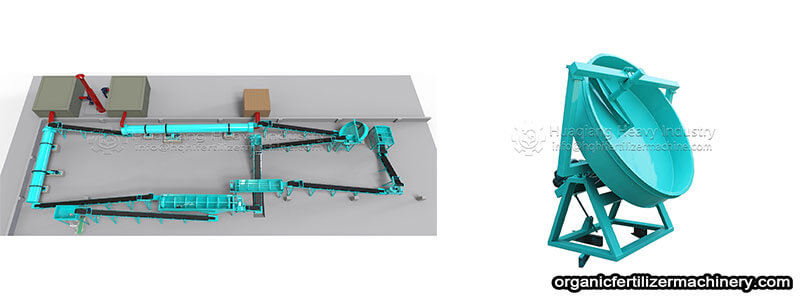

The process of disc fertilizer granulation machine: the raw materials are poured into the mixer for mixing and mixing, and then crushed after mixing, and then input into the pelletizing plate by belt conveyor; after granulation forming, the raw materials are sent to the dryer for drying, and then transported to the cooler for cooling through the elevator or belt conveyor for cooling. When the moisture content reaches below 6%, it enters the screening after cooling, and the large granular materials are crushed into fine materials through the return crusher, and the fine materials enter into the disc granulator, After being crushed, the coarse return material enters the granulator, and the finished product is packaged directly.

Organic fertilizer produced by disc granulator has the following characteristics:

1. Less investment: the total investment of organic fertilizer produced by disc organic fertilizer granulation machine can be saved by 30% compared with other processes;

2. Wide adaptability: the raw materials of disc granulation have wide adaptability, and the production formula is flexible, such as urea, ammonium chloride, ammonium sulfate, ammonium bicarbonate, etc. Phosphorus sources are: calcium superphosphate, calcium, monoammonium phosphate, diammonium phosphate, calcium magnesium phosphate fertilizer and so on. Potassium sources include potassium chloride, potassium sulfate, etc. However, it is difficult to granulate and dry high content compound fertilizer in the production process, which is suitable for the production of low nutrient compound fertilizer (20% – 35%).

3. The quality of the product meets the standard in nutrient, moisture, particle size, strength, water-soluble phosphorus and other indicators.

4. Easy to operate: disc granulation face-to-face, easy to control, flexible adjustment.

5. The production cost is low and the economic benefit is high.