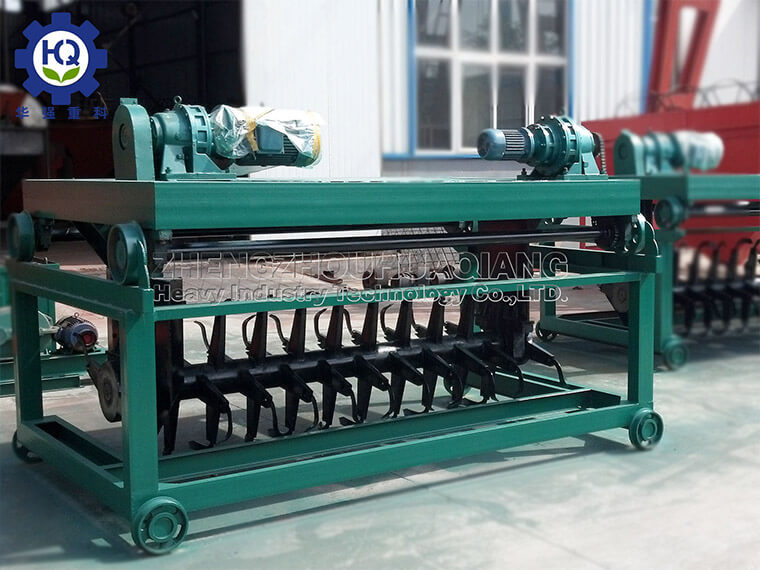

The working principle of the organic fertilizer turning machine is mainly based on the principles of mechanical stirring and turning. The core part usually includes one or more rotating mixing arms (also known as flipping shafts), which are installed on the main body of the machine. Each mixing arm is equipped with a set of blades or teeth at the end, which can cut, crush, and flip materials when rotating.

When the fertilizer turning and stacking machine is started, the rotating mixing arm will pick up organic materials such as chicken manure from the bottom of the pile and throw them upwards, while flipping the materials above to the other side of the pile. This process is constantly repeated, causing the entire stack to be flipped and stirred, thereby achieving uniform mixing and ventilation.

In addition, some advanced fertilizer turners are equipped with adjustment mechanisms that can adjust the working height and angle of the mixing arm according to the size and shape of the pile to adapt to different fermentation stages and material characteristics. Some dumpers are also equipped with a spray system, which can spray water during the process of turning to adjust the humidity of the pile body to optimize fermentation conditions.

In short, the organic fertilizer turning machine achieves effective turning and stirring of organic materials such as chicken manure through the principle of mechanical turning, accelerates the fermentation process, and improves the production efficiency and quality of organic fertilizers.