The organic fertilizer equipment mainly ferments and matures the organic matter mixture, adds trace elements such as nitrogen, phosphorus, and potassium according to the formula requirements, and then crushes it. It is stirred in a mixer, and after thorough mixing, the material is screened and the finished particles are sent to the finished product silo for packaging and storage. The organic fertilizer produced has a brown or grayish brown powder appearance, free from mechanical impurities and odorless.

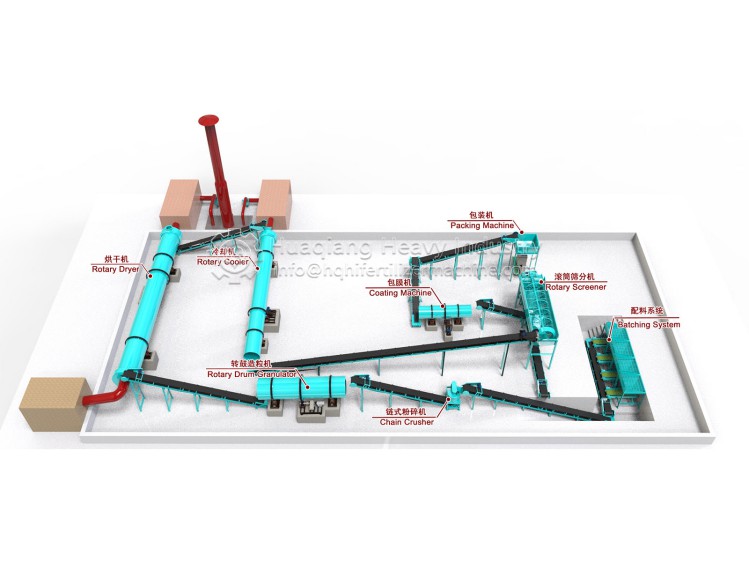

The process flow of the fertilizer production line for manufacturing organic fertilizers is as follows:

1. Ground stacking, using ground tipping machines, or feeding materials into fermentation tanks, using trough tipping machines.

2. Evenly sprinkle the bacterial agent, ferment in a pile to achieve heating, deodorization, maturation, and removal of miscellaneous bacteria and grass seeds.

3. Fermentation takes 7-12 days, and the number of times the pile is flipped varies depending on the temperature in different regions.

4. Completely fermented and matured, leaving the pond.

5. Use a grading screen for coarse and fine screening.

6. Crush the selected large blocks with a crusher and return them to the grading screen.

7. Mix the required trace elements with a pre mixer.

8. Use an organic fertilizer granulator for granulation.

9. Feed into the dryer and cooling machine.

10. Automatic packaging machine packaging for sale.

The organic fertilizer production line has three configurations: high, medium, and low. Large fertilizer factories need to adopt a complete set of production configurations to produce finished products that meet market requirements in terms of appearance and nutrient content. They have a significant advantage in promoting finished organic fertilizers. Low to medium configuration organic fertilizer production lines are suitable for small and medium-sized fertilizer factories. The sales range of finished organic fertilizers is limited to nearby areas, and some processes in the organic fertilizer production process require manual completion.