The non drying extrusion granulation process of double roller granulator has a wide range of applications in powder processing. Its characteristic is that it can process particles directly without humidifying or heating materials. It can be used for the processing of organic and inorganic fertilizer granules and feed granules.

The granulation process of double roller granulator is very short and convenient

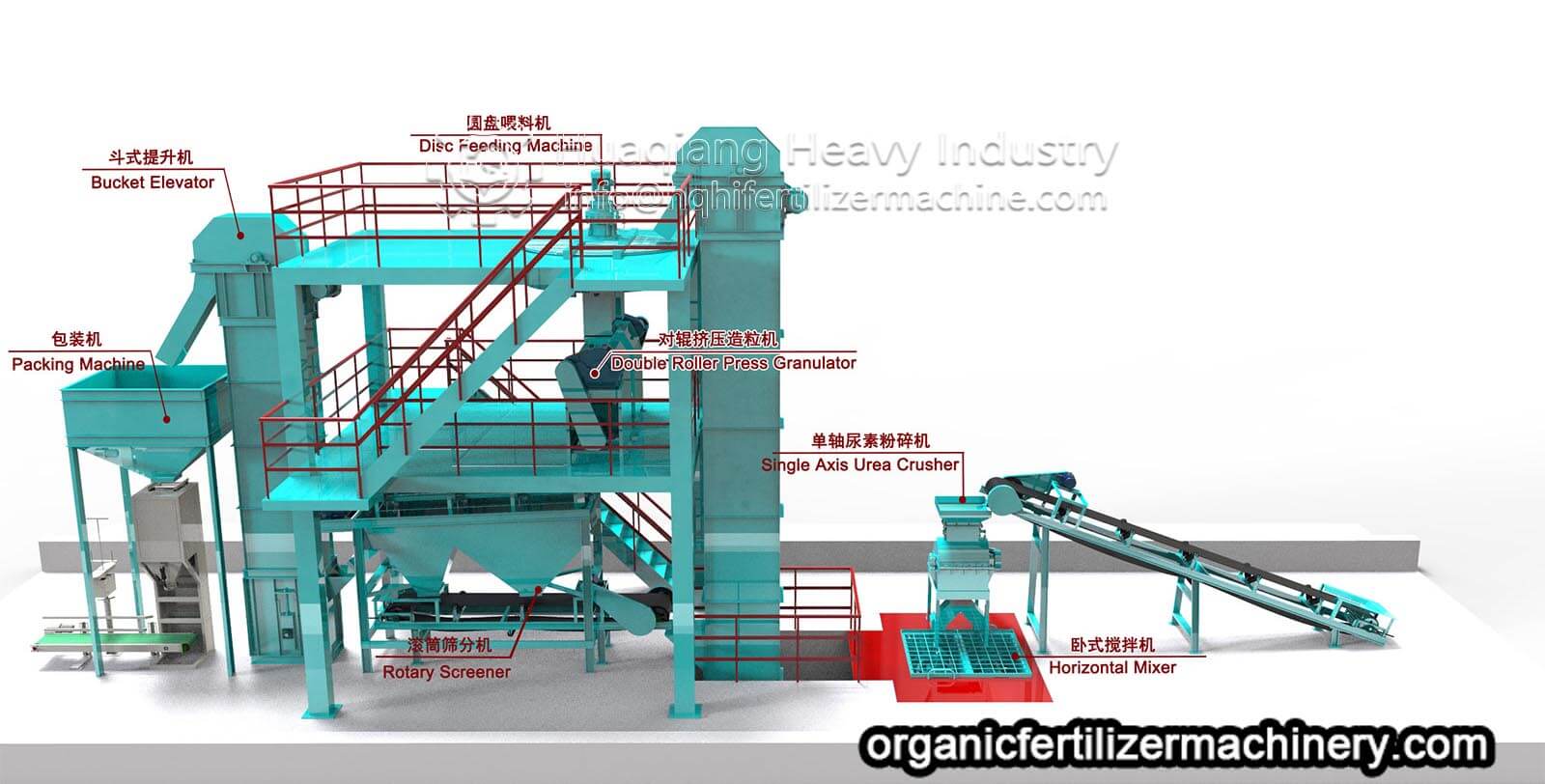

Automatic batching system → fertilizer mixer machine → double roller granulator → screening machine → packaging machine.

The fertilizer granulation machine uses the non drying extrusion granulation process, and there is no waste water or waste gas discharged in the production process, which will not pollute the environment. Extrusion granulation process is short, easy to operate, easy to realize production automation control and improve production efficiency. There are no special requirements for the properties and particle size distribution of raw materials, so the sources of raw materials are wide.

The granules produced by this fertilizer granulation machine are spherical with high content of organic matter, which can realize the granulation of pure organic matter. The organic particles can be inlaid and grow up with each other under a certain force. There is no need to add binder during granulation. The particles are solid and can be screened after granulation to reduce the energy consumption of drying.

My company produces fertilizer granulation machine has disc granulator, npk fertilizer granulator, double roller granulator, organic fertilizer granulator machine, drum granulator, flat die pelleting machine, and ring die pelleting machine. Fertilizer granulator machine price concessions, stable operation, convenient maintenance, quality assurance, the majority of users like!