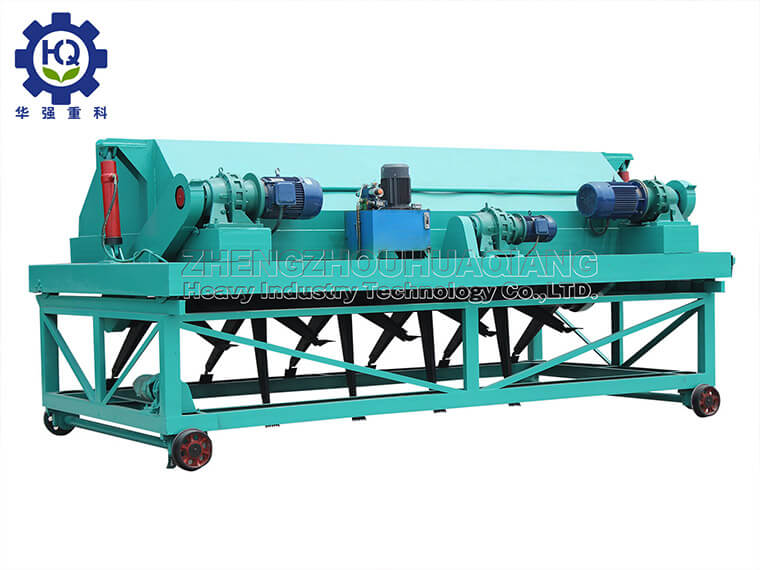

Fermentation of cattle manure into organic fertilizer through biological aerobic fermentation technology is a good method for processing cattle manure in cattle farms. The production of organic manure by cattle manure fermentation requires the addition of biological starters and the turning of materials. Is necessary. So what should you pay attention to when using the compost windrow turner?

1. The fuel tank should be filled with oil before the compost windrow turner is used. Remember to add an appropriate amount of fuel and not overfilled; add water to the tank of the compost windrow turner.

2. Regularly add grease to the oil injection holes marked on the body of the compost windrow turner, but the chain should be coated with engine oil, but not grease.

3. The operator regularly checks the tightness of the compost windrow turner belt. If the belt is too loose, it will make the stacker difficult to catch fire. (For 2m compost windrow turner)

4. The operator should regularly check the use of the compost windrow turner screws and blades to ensure that the stacker is normally put into use.

5. The operator of the cattle manure fermentation compost windrow turner should advance the small throttle at a uniform speed during the material stacking process, and cannot operate with the large throttle.

6. The cattle manure compost windrow turner cannot be hard-started, and it should be started outside the materials, otherwise the motor may be burned and cause machine failure.

During the fermentation process of the organic fertilizer dumper, the raw material pellets of the organic fertilizer dumper are fully contacted and assimilated with the air. A large amount of fresh air can be contained in the pile, which helps aerobic microorganisms to generate fermentation heat and increase the pile temperature; When the temperature is high, the filling of fresh air can reduce the stack temperature and reduce the water content in real time with the fertilizer making process. In addition to the evaporation formed by heat conduction, the tipping machine will turn over the raw materials to form a forced steam hair.