NPK fertilizer manufacturing process must be screened to obtain qualified appearance of granular compound fertilizer. In the screening machine feeding process, what should pay attention to?

Precautions for operation of screening machine:

1. When the screening machine is running smoothly, start the feeding and discharging equipment for commissioning.

2. Close the seal isolation hood after normal discharge (the seal isolation hood should always be in the closed position during normal operation).

3. Check the discharging particle size, leakage and dust.

4. Run for half an hour, check all parts carefully, and deal with problems in time.

5. The operation should be checked frequently during the working process. If the operation is found to be abnormal or abnormal sound, it should be shut down and checked in time to find out the reason and eliminate the fault.

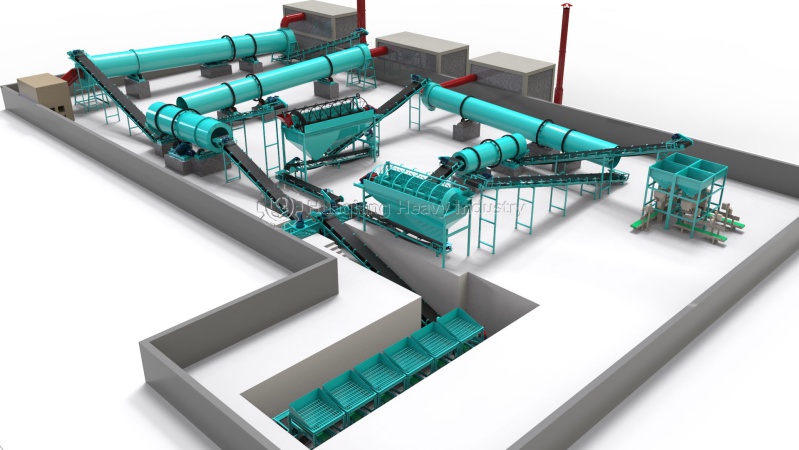

The fertilizer treated by NPK fertilizer granulator needs to be dried. Because the particles have a certain temperature, the fertilizer particles are transported to the cooler for cooling. After cooling, the particles are sent to the coating machine for coating, and finally sieved. The appearance is very good.