Organic fertilizer production line processes domestic sludge to produce fertilizer

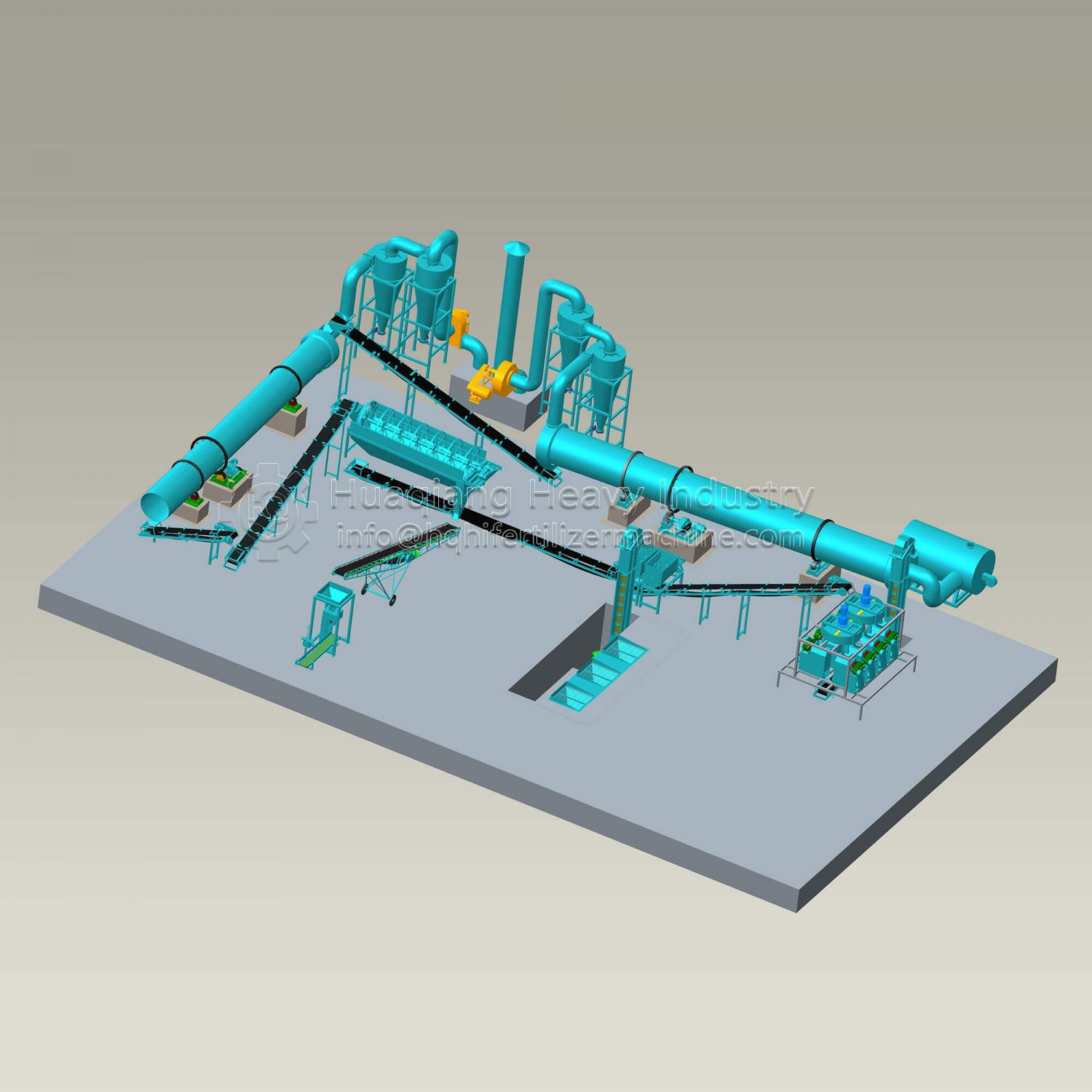

1. Adjust the moisture content of raw materials: the water content of sludge from the water treatment plant is generally relatively high, about 75% – 80%. It is generally anaerobic fermented, and the content of harmful bacteria is not high. When it is transported back to the fermentation plant, the raw materials with low moisture content should be placed under the fermentation tank, and then the water-absorbing auxiliary materials, such as domestic garbage and crushed crop straw and branches, should be placed above to make full use of the liquid organic fertilizer, It can increase all kinds of nutrients in the raw material to be sufficient, and the water content of the material in the fermentation can be 50% – 55%.

2. Adding sludge starter (special starter for sludge reduction): adding special starter for sludge reduction to the sludge is generally added before fermentation, and the fermentation bacteria are evenly mixed with the sludge through the function of throwing and stirring by the tilting machine. The addition amount of composite starter is generally about 0.1% – 0.3%. Just put the sludge starter into the sludge.

3. Fermentation of organic fertilizer composter: after high-temperature fermentation, it can effectively kill pathogenic microorganisms and ascaris eggs in the sludge, fix heavy metals in the microorganisms, or turn them into insoluble carbonates, and prevent heavy metals from entering the food chain. There are two kinds of fermentation methods: ground strip fermentation using ground tipper; And trough-type tipping fermentation with trough-type tipping machine. The production process of sludge organic fertilizer introduced this time uses the tank type fermentation tipping machine.

4. Material crushing: because the fermented material contains small lumps, which is not conducive to the granulation of the finished product, the material can be crushed at this time, and the organic fertilizer crusher can be used.

5. Material mixing: the crushed materials are transported to the batching bin, then sent to the main conveyor through automatic batching, and then sent to the mixer for mixing.

6. Material granulation: small and medium-sized organic fertilizer plants generally use disc granulator to granulation, which can save investment costs and achieve a high pelletizing rate of more than 93%. There are three kinds of particles: large, medium and small. The angle of the granulation disk must be adjusted to a certain position. The angle depends on the size of the particles. The larger the angle, the smaller the particles. The smaller the angle, the larger the particles.

7. Drying and cooling of organic fertilizer: the granulated semi-finished organic fertilizer particles are sent to the dryer through the main conveyor for drying, and the dried finished organic fertilizer particles are sent to the primary screening machine through the conveyor to sort out large, medium and small particles. The larger particles are sent to the pulverizer through the return belt for crushing and re-granulation. The medium and finished materials are sent to the cooler through the conveyor for cooling, because the particles have a certain temperature, the particles are sent after cooling, The fine powder is separated by two sieves.

8. Finished product packaging: the screened finished organic fertilizer particles are sent to the organic fertilizer automatic packaging machine through the conveyor, and the finished bio-organic fertilizer can be produced by measuring and packaging.