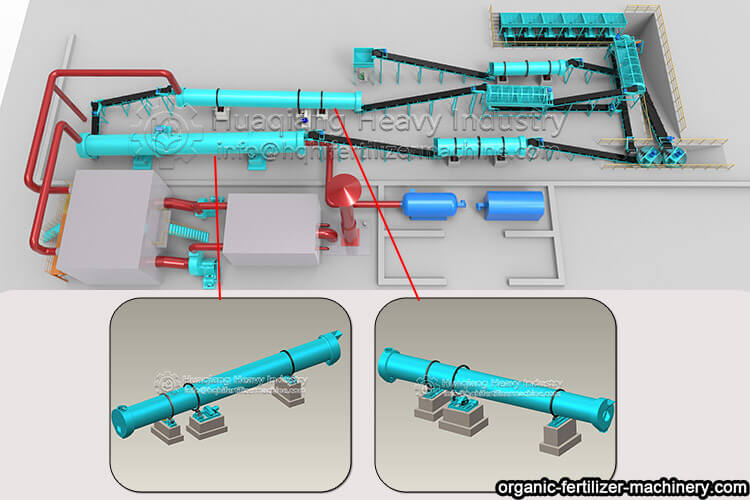

In the process of compound fertilizer production line processing, it is necessary to dry and cool the materials. At this time, dryer, cooler and screening machine are needed. Many customers are not familiar with the fertilizer processing process. Here is how to dry and cool the materials in the organic fertilizer production line

The particles processed by NPK fertilizer granulator to be dried are transported to the feed inlet of the feeder by belt conveyor, and the granular materials flow into the drying cylinder along the feeder chute. The feeder is inlaid on the outside of the drying cylinder. With the overall rotation driven by the deceleration drive system, the granular materials move backward with the rotation of the drying cylinder, and the heated hot air is blown into the feeder end. It is in direct contact with the material of the drying cylinder to evaporate its water vapor and dry it. In the drying process, according to the drying degree of materials, the deceleration drive system can adjust the rotation speed through the frequency converter.

The middle induced draft hood will draw the steam out of the drying cylinder. Then, with the rotation of the drying material, it enters the cooler again. Under the action of the middle induced draft hood, the natural wind enters the cooler from the unclosed end of the cooler. With the rotation of the cooler, the material is picked up and the material temperature is directly reduced to the natural temperature. After that, the granular materials will enter into the drum screen, and the unqualified materials will be screened out from the drum screen, and the qualified materials will directly enter the next packaging section.