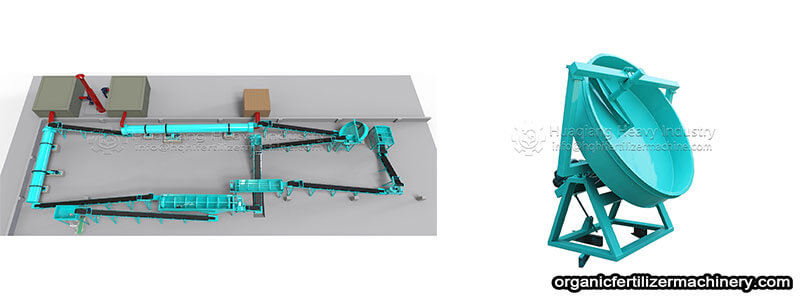

The disc organic fertilizer granulation machine is a granulator which is installed on the central shaft in the center of the disc, which is supported on the bearing of the frame and driven by the transmission device. The inclination angle of the disc can be completed by the adjusting mechanism controlled by the angle adjusting hand wheel according to the requirements. The disc surface is equipped with a scraper which is fixed on the scraper frame. The upper and lower blades can be adjusted in time.

The disc organic fertilizer granulation machine uses a conveyor to transport powdery materials into the disc. The powder and the liquid droplets sprayed by the material liquid sprayer are combined to form a small particle group. In the process of rotation, due to the gravity and centrifugal effect produced by the inclined disc in the rotating process, the small particles roll down to the edge of the square plate and adhere to the powder continuously to increase the particles. At the same time, due to the friction between the material and the disc, the particles roll up with the disc. When reaching the position of the scraper plate, the non spherical powder passes through the gap between the scraper plate and the bottom of the disc, while most of the particles flow down the scraper plate to the edge of the disc. During the rolling process, the particles adhere to the powder again. After repeated cycles, the particles from small to large reach the finished product size and overflow from the edge of the disc fertilizer granulation machine.

The main factors affecting the granulation of disc organic fertilizer granulator are the diameter of disc, the inclination angle of disc, the height of disc edge, the rotating speed, the position of material liquid spraying and the position of scraping plate. Therefore, a skilled granulator plays an important role in mastering the equipment. Disc granulator, which can complete the production task with the maximum efficiency and phase through the adjustment of various aspects.