The technology of fertilizer granulation without drying is mainly used for products with low moisture content. Generally, the moisture content below 10% is a critical value. (some materials can reach 16%, for example, some materials only contain crystal water). Part of the organic fertilizer manufacturing process has low moisture content, which can eliminate the need for drying and save energy.

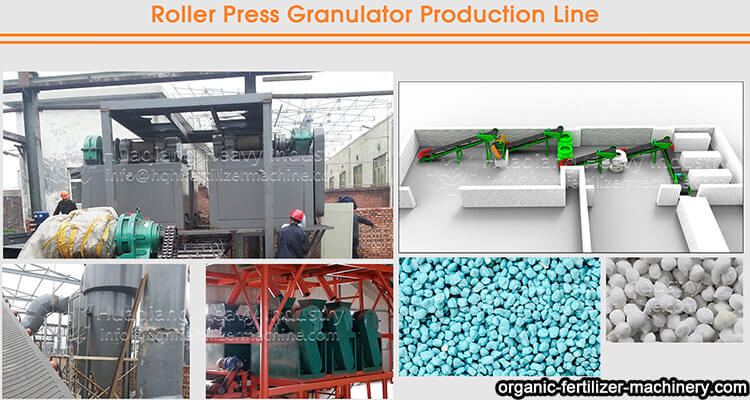

Dry granulation

Double roller granulator belongs to dry granulation equipment, without drying process. It has high granulation density, good fertilizer efficiency and full organic matter content. The particles are flat and round, which are suitable for compound fertilizer. Most of the particles produced by dry granulation are irregular particles (such as common granular potassium fertilizer), and the shape is similar to that of small crushed stones. The double roller granulator can produce all kinds of high, medium and low concentration NPK compound fertilizer and organic-inorganic compound fertilizer granulation, which meets the requirements of energy conservation and environmental protection.

Structure

This dry powder extrusion granulator is mainly composed of five parts: frame, head, reducer, motor, and crusher. It has the characteristics of simple structure, high stability, easy operation and maintenance, and wide adaptability of raw materials.