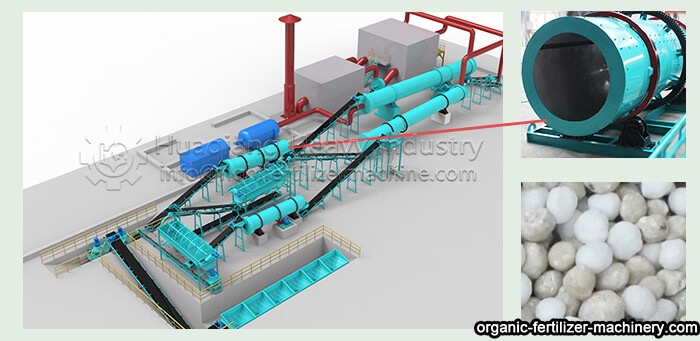

Huaqiang factory’s fertilizer equipment drum granulator solves the problem of wall sticking. The fertilizer drum steam granulation manufacturing process has large output flexibility. Rotary drum granulator is cylindrical and has good heat preservation effect. The steam is used to increase the temperature of the material during granulation to meet the liquid phase required for granulation, which can greatly reduce The water content of the material during granulation reduces the load of the dryer and increases the output of the whole machine.

Granulation mode of drum granulator

The double roller granulator uses dry granulation, while the main working mode of drum granulator is wet granulation. After the basic fertilizer is humidified in the cylinder by a certain amount of water or steam or gas ammonia or phosphoric acid or nitrogen solution, the compound fertilizer granulation process of chemical reaction and heat supply or the cold granulation process of compound fertilizer with a small amount of water is added. Under the condition of temperature and humidity, with the help of the rotary movement of the cylinder, the material particles are squeezed and agglomerated into balls.

Improvement of drum granulator

The drum granulator has a wide range of adaptability to the production of raw materials. It can be used in combination with low-solubility and high-solubility materials as required, and can also be used with some organic matter and medium and trace elements. In the organic fertilizer manufacturing process, the problem of wall sticking in the drum granulator is more serious, which directly affects the movement of the material, and affects the ball formation rate and the roundness of the granules. To solve this problem, we have developed a high lining on the inner wall of the granulator. The movable inner lining of molecular materials solves the problem of wall sticking of materials and plays a role of anti-corrosion and heat preservation.

The drum granulator is suitable for nitrogen, phosphorus and potassium nutrients, with flexible nutrient distribution ratio. It can process high nitrogen compound fertilizer, all kinds of special fertilizer, organic and inorganic compound fertilizer with more than 20% nitrogen element.