The complete set of mixed fertilizer production equipment is suitable for dry mixing of multiple basic fertilizers with nitrogen, phosphorus, and potassium fertilizers through physical methods to produce a mixed fertilizer (BB fertilizer) that combines multiple fertilizers and single fertilizers. It integrates ingredients, mixing, and quantitative packaging, and can automatically complete the preparation of 3-6 materials according to the formula; By modifying the formula for different crops and soil conditions in different regions, different BB fertilizer products can be produced.

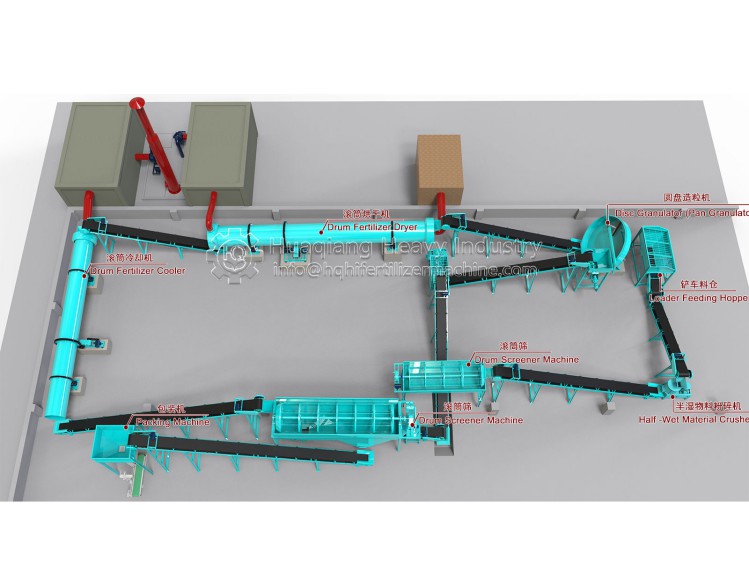

The BB fertilizer mixing and stirring equipment mainly consists of the following equipment: a storage silo; Feeder; Measurement scale; Mixer; High angle belt elevator; Quantitative packaging machine; Automatic sewing machine; Finished product transportation belt conveyor; Computer control system. The process is as follows: storage system → feeding system → metering system → conveying and lifting system → mixing and stirring → automatic packaging and sewing → finished product belt transportation → computer control system.

The characteristics of the complete set of mixed fertilizer production equipment:

1. Large batch ingredients, large batch mixing, fast single bag packaging;

2. The types of ingredients can range from 2 to 12;

3. Production capacity ranging from 15 to 60 tons, with special customization up to 100 tons;

4. The ingredient accuracy can reach 0.5%, the mixing is uniform with no difference in content, and the packaging accuracy is better than 0.2%, which is within 100 grams;

5. Have the ability to print reports and inquire about the accuracy of instant ingredients at any time;

6. Equipped with on-site or remote monitoring system functions, connected to a large screen to display the current recipe;

7. The entire production line has a compact structure and is aesthetically pleasing, making it particularly suitable for leaders and agricultural material distributors to visit.