Organic fertilizer raw materials come from a wide range of sources, including livestock and poultry feces, fungal spore residue, distiller’s grains sludge, etc., which can be targeted as organic fertilizer raw materials. These raw materials used to be troublesome waste to handle, with relatively low acquisition prices, giving the finished organic fertilizer a greater profit margin. The organic fertilizer production equipment is centered around granulation equipment, producing finished granular organic fertilizers that enable effective recycling and utilization of fertilizers. The large amount of livestock and poultry manure generated by breeding farms is used to produce green organic fertilizer, which is returned to the fields for organic agriculture. Agricultural waste and fruits are fed to various livestock and poultry, forming a natural green biological chain and maintaining ecological balance.

Organic fertilizer processing equipment is a complete set of production equipment that produces natural organic fertilizers from organic rich raw materials such as animal manure and plant straw, after a series of processing treatments. Organic fertilizer is suitable for crops such as wheat, rice, peanuts, fruits and vegetables, which can improve crop quality and fruit quality, and is beneficial to human health. It is the best choice of fertilizer for pollution-free green food cultivation. The overall process can be divided into: raw material collection, raw material ratio, raw material moisture control, raw material fermentation, raw material crushing, raw material drying, granulation, and packaging into bags.

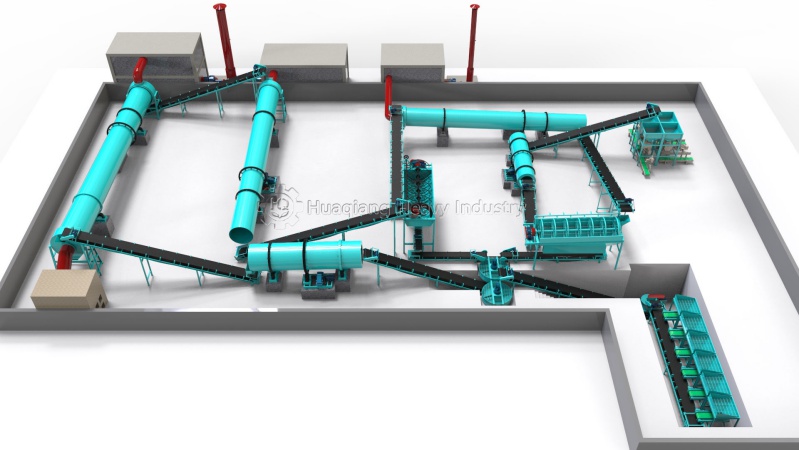

The organic fertilizer production line process required for producing animal manure organic fertilizer:

1. Raw material fermentation; 2. Automatic batching of raw materials using computer belt scales; 3. Dedicated organic fertilizer crusher and mixer; 4. The new type of organic fertilizer granulation machine is commonly known as drum granulation or extrusion granulation; 5. Drying organic fertilizer particles with a dryer; 6. Cooling machine for organic fertilizer particles; 7. The screening machine screens out qualified organic fertilizer particles; 8. Coating machine coating particles, smoother; 9. Packaging scale automatically fills organic fertilizer particles; 10. Sealing.

In this fast developing information age, organic fertilizer equipment needs to adapt to the competition and development of the market to adapt to better development, constantly accelerate the speed of upgrading, and also accelerate the production efficiency of enterprises, so that the organic fertilizer equipment of enterprises can be recognized by more users in the market, more applications in the development of agricultural ecology, and promote the development of green agriculture in China.