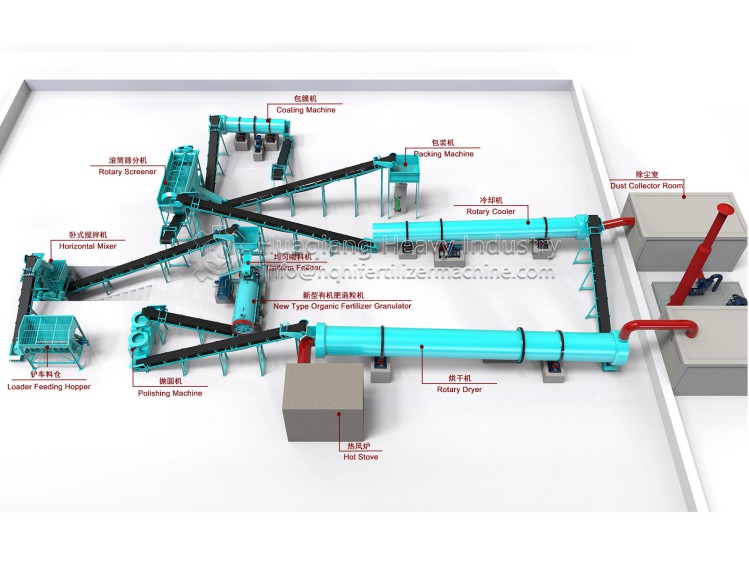

Process flow of sheep manure organic fertilizer production line

1. Mix sheep dung with proper amount of straw powder. The amount of mixing depends on the water content of sheep dung. Generally, 45% of the water content is required for fermentation, that is to say, knead it into a ball by hand, see water in the fingers, but do not drip, and release it to dissolve. Then add corn flour and bacteria. The role of corn flour is to increase sugar content for bacteria fermentation, so that multi-dimensional complex enzyme bacteria take advantage.

2. Add the prepared mixture into the mixer for mixing. The mixing must be uniform, transparent and free of raw blocks.

3. The mixed ingredients are stacked into strips with a width of 1.5 meters to 2 meters and a height of 0.8 meters to 1 meter, which are flipped once every 2 days with a tipping machine.

4. The compost is heated for 2 days, odorless for 4 days, loose for 7 days, fragrant for 9 days, and composted for 10 days (that is, the temperature on the second day of composting can reach 60 ℃ – 80 ℃, killing diseases and insect pests such as Escherichia coli and insect eggs; the stink of sheep dung is eliminated on the fourth day; the compost becomes loose and dry on the seventh day, full of white hypha; a kind of liquor starter flavor is produced on the ninth day; the compost is fermented and matured on the tenth day).

5. After a little drying, it can be crushed by a semi-wet material crusher, granulated by an organic fertilizer granulator, dried and dehydrated by a dryer, and then screened by a screening machine. The finished organic fertilizer is ready for packaging and storage.

The sheep dung is mainly produced by aerobic tank fermentation: this is a common method to treat sheep dung at present, and it is also suitable for the commercial production of sheep dung organic fertilizer, which is conducive to standardized production. It uses biological characteristics and mechanized technology to completely decompose sheep dung and transform organic matter into organic matter, carbon dioxide and water by using natural microorganisms or inoculating microorganisms. This method has a short fermentation time. Generally, sheep dung can be fully fermented and decomposed in about 15 days, and it is easy to realize industrialized scale production, is not affected by weather and season, and has little pollution to the environment, which is conducive to the commercial production of sheep dung organic fertilizer.